The development trend of corrugating machine

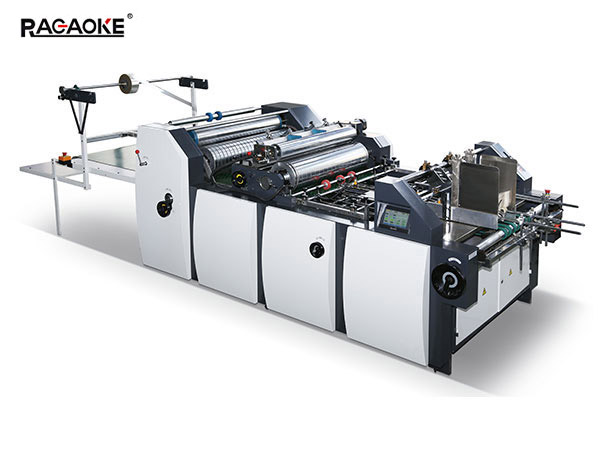

Improve productivity

Mainly by increasing the working width and working speed of the corrugated board production line or corrugated board printing machinery, increasing the work volume per unit time, thereby improving the production efficiency of the corrugated box equipment. In recent years, with the increasing domestic demand for corrugated boxes and the continuous growth of carton manufacturers, large-scale production has become the development trend of China's carton manufacturing industry. Carton manufacturers want to carry out large-scale production, and put forward higher requirements for the production efficiency of corrugated carton machinery.

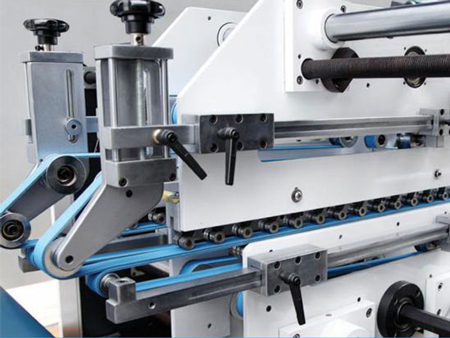

Improve job quality

Improve the quality of corrugated cardboard by improving the adhesive strength of the corrugated cardboard production line and the low-weight processing capacity. For the corrugated cardboard box printing and slotting machine, the quality of carton printing is improved by improving the color registration accuracy and the number of anilox roller lines. Since 2000, domestic corrugated cardboard box packaging users have changed their traditional transportation packaging concepts and began to pursue sales packaging, putting forward higher requirements for the printing quality and external performance of corrugated cardboard boxes. In addition, domestic corrugated boxes are generally soft in texture and insufficient in breaking strength. As the carton giants accelerate their entry into China, this disadvantage will become more and more obvious.

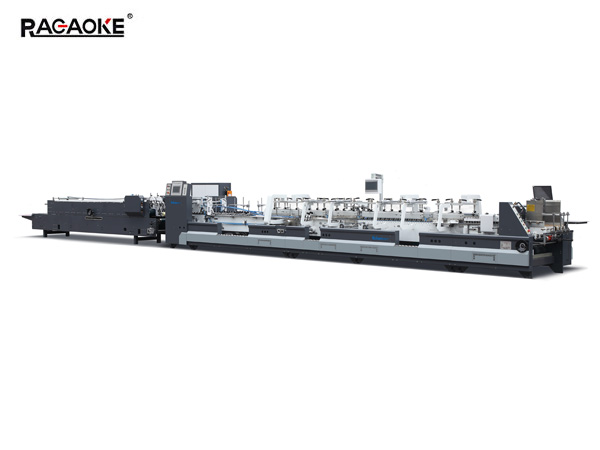

Improve equipment operation quality

Mainly refers to improving the operation stability, automation level and control convenience of corrugated box machinery. Improve the operation stability of the corrugated box equipment by improving the design structure; improve the automation level and control performance of the corrugated box equipment by continuously introducing electrical components and computer program control systems. So as to ensure the long-term, high-speed and stable operation of the equipment.